Engine!

So my spare engine that came with the bike is completely gubbed, big end bearing(the one that joins the conrod to the crankshaft) is almost non-existent.

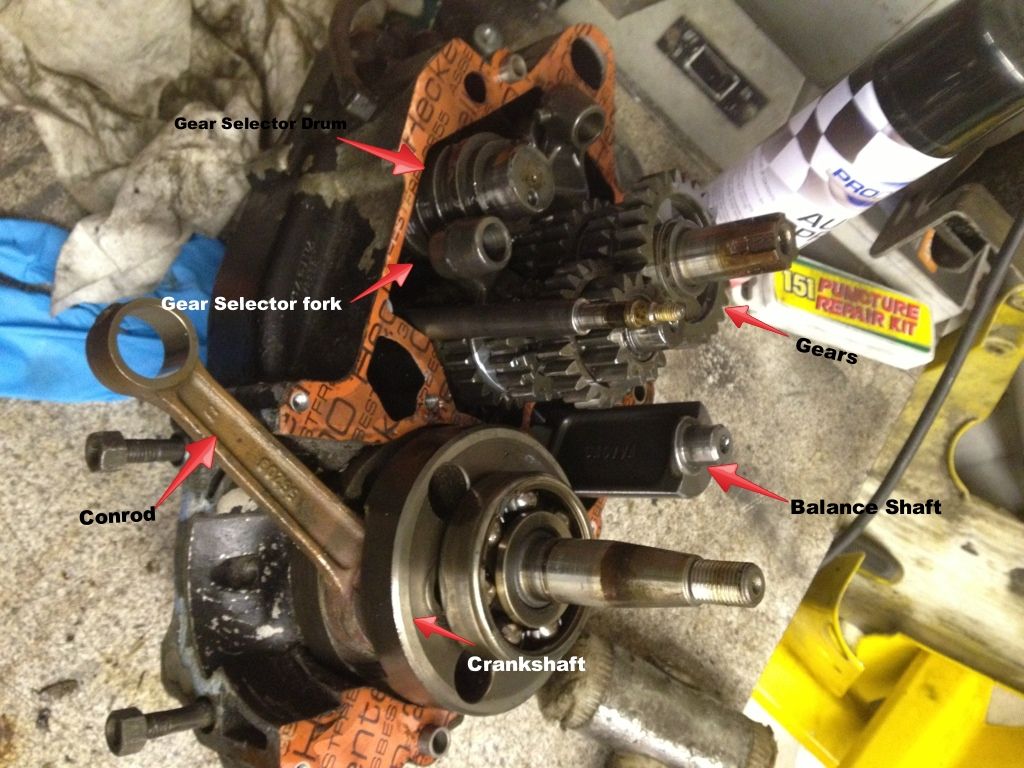

Here is an image of the engine split, including all the gears, the crankshaft and the balance shaft, which is used to balance the engine vibrations, in order to make the engine vibrate less when running!

This is an image of the destroyed big-end bearing at the crank end of the conrod:

From the movement cause by the damaged bid-end bearing, you can see the differentiating colour at the bottom of the conrod, caused by the heat of the excess movement.

I am going to be venturing into tuning my engine a little, and seeing what rear wheel brake horse power I am able to get from my 125. As the model I have bought is an evo1(although it has a 6-speed bottom end) it did still have the 35mm carburetor that my year came with as standard, the mikuni tm35.

The best picture I have of it at the moment:

It also came with what a lot of people say is the best expansion chamber(exhaust) - which can make a big difference on a 2 stroke, and with the "bunny-eared" airbox - which is also apparently the best - which i do not have a picture of at the moment.

Engine No2

When I first bought the bike it would not turn over with a fresh battery, which meant the first thing to check was the starter motor, and I tested that by connecting the 12v battery directly to the positive terminal of the starter motor, and it turned over but made a horrible knocking noise, then the starter solenoid was checked and it proved to be that which was broken. Checked with a multi-meter. Next on the to-do list was to find the source of the knocking noise, which was narrowed down, simply by listening, to the flywheel. Which is this part of the engine, usually inside a casing of course.

The flywheel is on the end of the crank and is held in place by something called a woodruff key which looks like this:

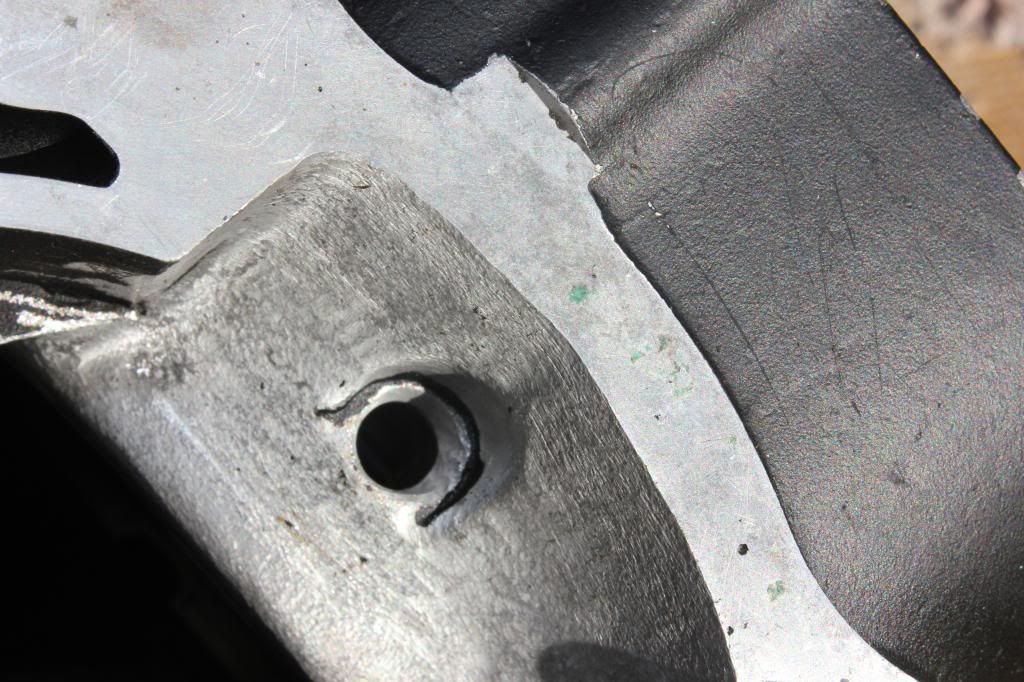

But anyway mines had snapped inside and it had melted into the flywheel, allowing the flywheel to move, which was the source of my knocking noise. More piccies:

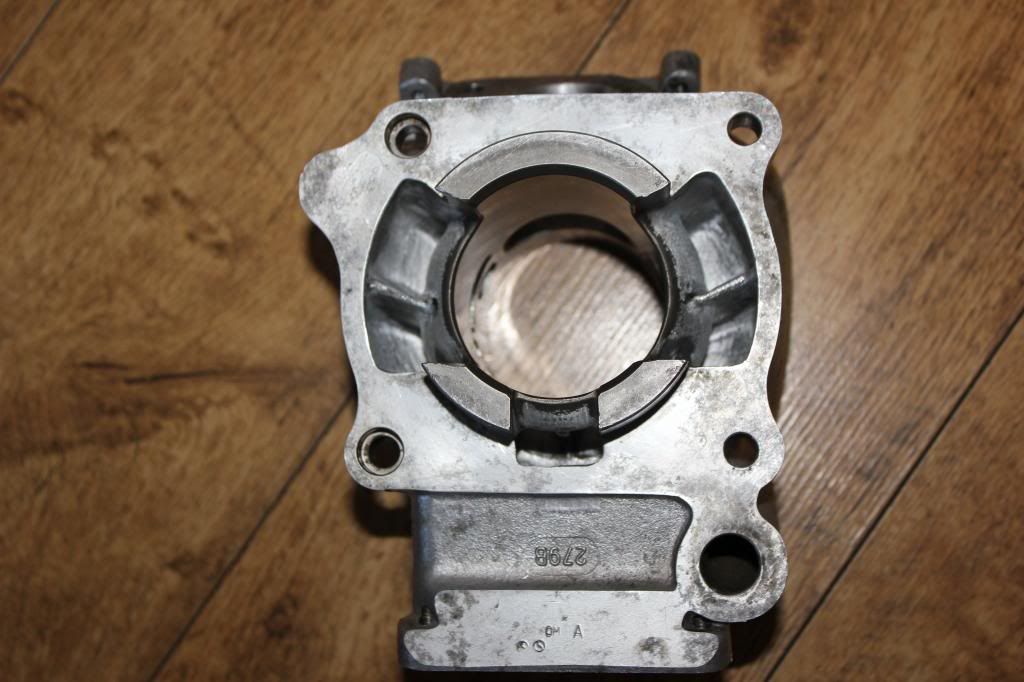

Okay, now to the tuning side of things. I am aiming for a low squish, luckily there is a cylinder head for the Mito by Cagiva. It is called the 200H, all of the variations of the Mito's cylinder heads are called 200 and a letter. The 200H is the best cylinder head for running a flat top setup with a squish of 0.8mm - it becomes unsafe to run much lower than this. I will be running a single ring flat top piston, for less friction, as every little helps in such small capacity engines. It means less heat is transferred away from the piston to the cooler cylinder walls, as there is less area touching compared to a twin ring setup. This can mean less reliability, but as this bike will only be a toy then it will not be much of an issue. My 2 engines however came with 2 200C cylinder heads, therefore I had to purchase a 200H, which is quite a rare part. I bought it from one of the great guys from the forum.

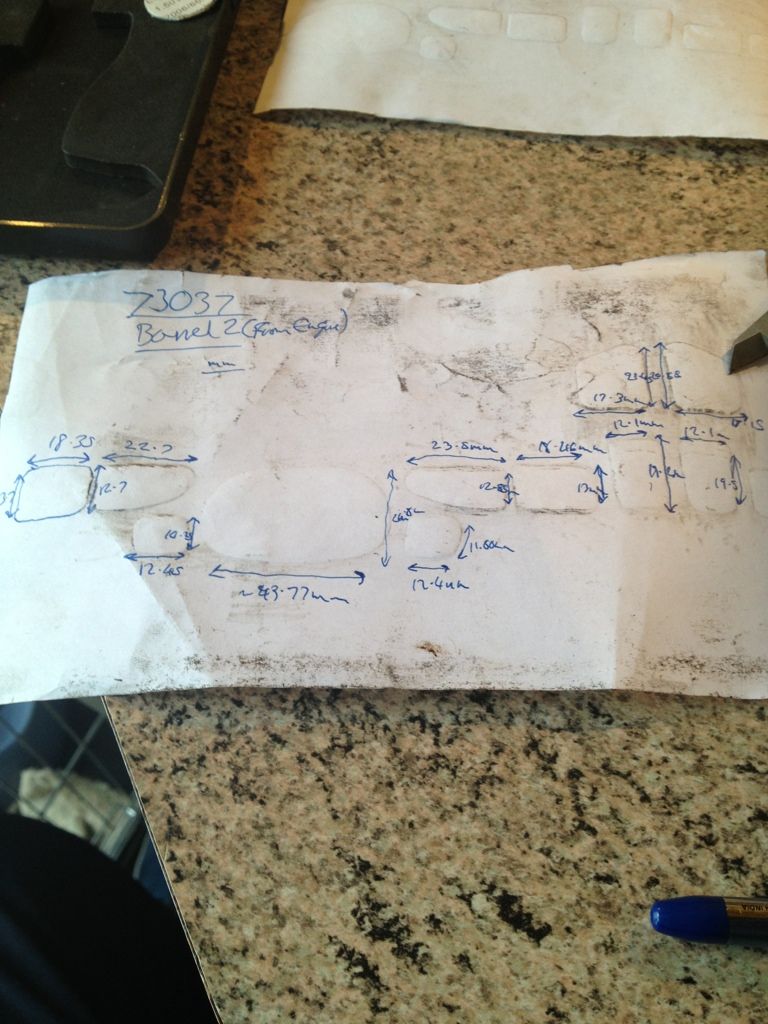

Now the next step for the engine in my eyes is to get it ported, the person/company I will be getting to do my porting is Mick at Mick Abbey Tuning, I am just finishing splitting my second engine to send it away to get the barrel ported and also to get the crankcases ported to match. There is large gains to be had from the process of porting. As I am getting it ported I decided to do a port map before and after, and measure the exhaust port, so that I could see the differences, and if Mick allows I may post my after port map here.

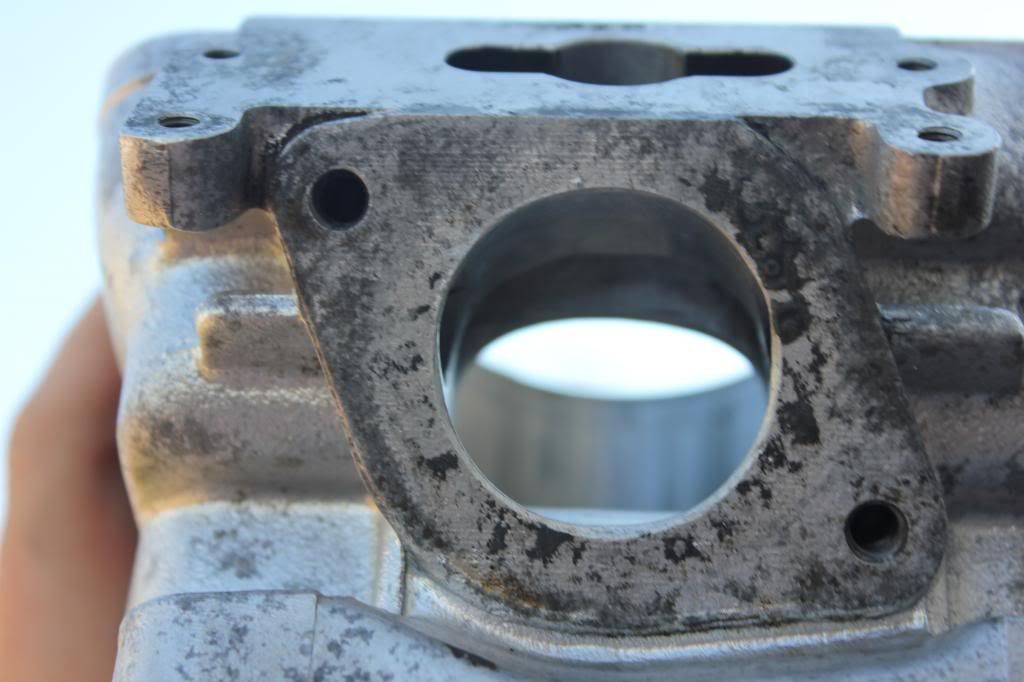

before:

I did both of my barrels, but this one will be getting ported so i shall post this one. I should have mentioned, for anyone who knows the Mitos and their barrels then I am running a 73037 barrel.

Many thanks to people on the forum, they help me understand things and anything i get stuck at they help guide me! Also to my dad who has taught me almost everything I know about bikes and mechanics, and is helping me through my first project.

The engine is prepped to go to mick abbey, will be getting posted in the next few days.

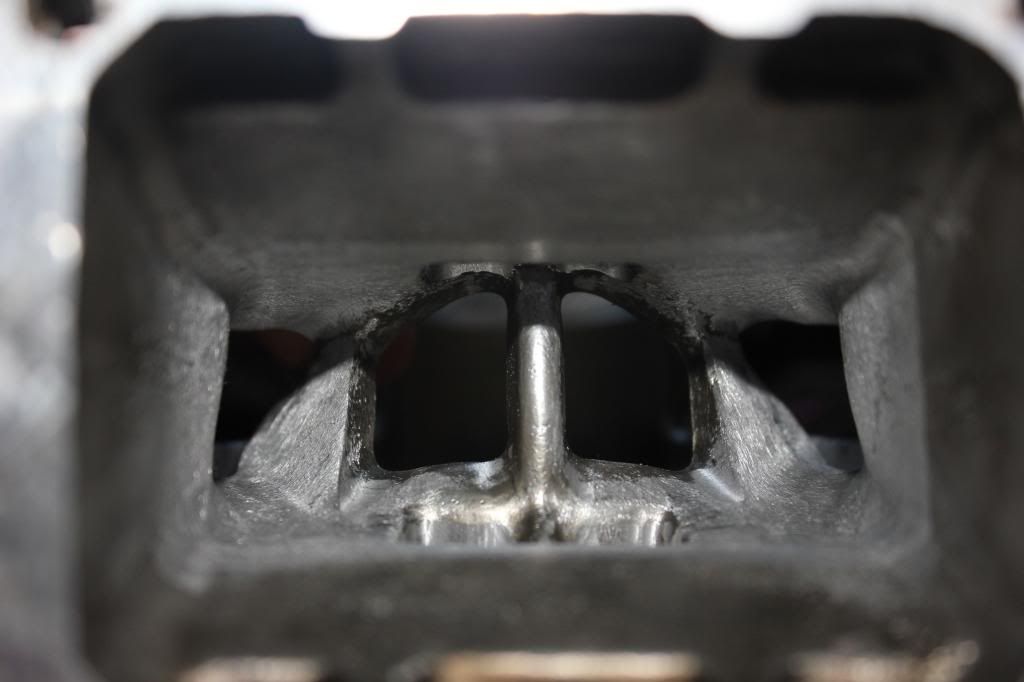

The powervalve was fairly coked up and also decided to take the pv apart.

All organised and ready to go.

lovely coked up powervalve blade.

part of the pv assembly.

Where the rest of my good engine is sitting at the moment.

This Blog is about to get pic heavy.

Porting done by Mr Mick Abbey, including worked crankcases.

The Exhaust Port Has Been Raised by about 1.5mm I believe and I will be doing port duration calculations.

Enlarged oil feeds through to the mains.

Hi, can you share your cylinder mapping after porting. Just to know the differences against standard mapping

ReplyDeleteI will get round to it at somepoint! lol Uni is taking up a lot of my time.

ReplyDelete